Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

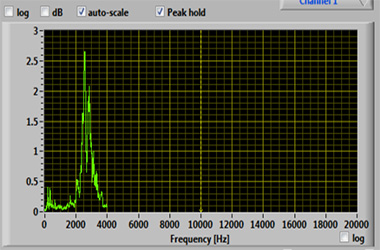

Machinery failure in compressor systems can often lead to shutdowns, high repair costs, and increased safety risks. Recently, at a compressor pump station, new vibration sensors were installed on a reciprocating compressor that appeared to be functioning properly. The sensors immediately reported problems with the compressor. As the sensors were new technology, the technicians were suspicious of the data. When the sensors passed all performance checks, the technicians were conflicted about bringing in a vibration consultant, even though it was a necessary step, due to the costs and shutdown times to which it would lead.

Industrial Gas Pumping Station

To alleviate the costs and shutdown time concerns, the technician used a Digiducer and a laptop to collect vibration plots from the compressor. These plots and plots from similar, working machines, were sent to a vibration expert remotely for comparison and analysis. The expert quickly determined that the compressor was working incorrectly and further action was needed. This early analysis allows experts to determine the need to go on-site or if there is a simple fix. The Digiducer saved time and money by allowing the expert to do a remote, early diagnosis.

Compression Vibration Signature

The plug-and-play nature of the Digiducer allows technicians to acquire detailed, accurate vibration data. Using a smartphone or laptop makes it easy for technicians to send vibration plots off-site for analysis. Remote investigation saves valuable time, while allowing technicians to quickly address major malfunctions with confidence. As a USB accelerometer, the Digiducer allows important vibration measurements to be taken with most Windows, macOS, iOS, and Android devices, saving facilities valuable time and money.

Laptop acquiring vibration data through a Digiducer